- Category:

Manufacturing

- Stack:

React, Fastify, TypeScript, MongoDB, Redis, AWS

- Date:

15 May, 2025

The Challenge

A leading electronics manufacturer struggled with high defect rates and lack of visibility across PCB (printed circuit board) assembly lines. Existing quality control was manual, slow, and reactive — issues were only found after entire batches were completed, resulting in delays and scrap loss.

Our Solution

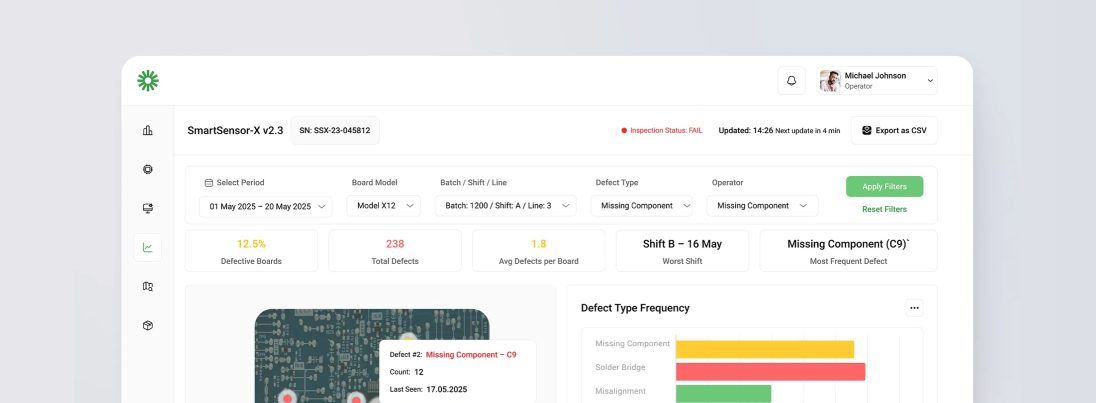

We built a real-time defect detection and analytics platform that integrates directly with smart cameras and inspection hardware. The system processes image data and operator logs to provide:

- Instant defect type classification (e.g., Missing Component, Solder Bridge)

- Shift and batch-level quality insights

- Smart filters and trend tracking dashboards

- CSV export and alerting capabilities for operators

Results & Impact

- Defect rate reduced by 32% in the first 2 weeks after deployment

- Inspection feedback time dropped from hours to under 5 minutes

- Customizable filters and reports saved operators ~40% of time per shift

- Real-time sync between factory sensors and dashboards improved responsiveness